Mechatronics | MEDICAL DEVICE | Solidworks | Arduino

Surgical Robot

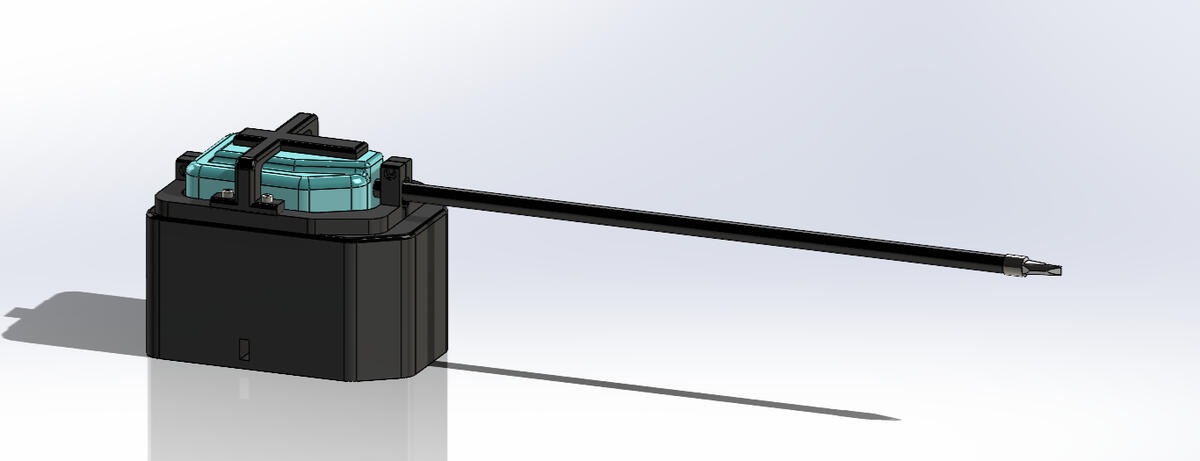

I purchased a decommissioned surgical robot instrument from an Intuitive Surgical DaVinci Surgical Robot. I am reverse engineering the instrument to design a motor housing, electronics, and Arduino code to control the instrument. The end goal is to attach this system to ARM-E, the robot arm that I am designing.

(Mar 2024 - Present)

DaVinci Robot

The DaVinci system from Intuitive Surgical is one of the FDA approved surgical robots. It consists of four arms each carrying an instrument. I purchased an old needle driver instrument.

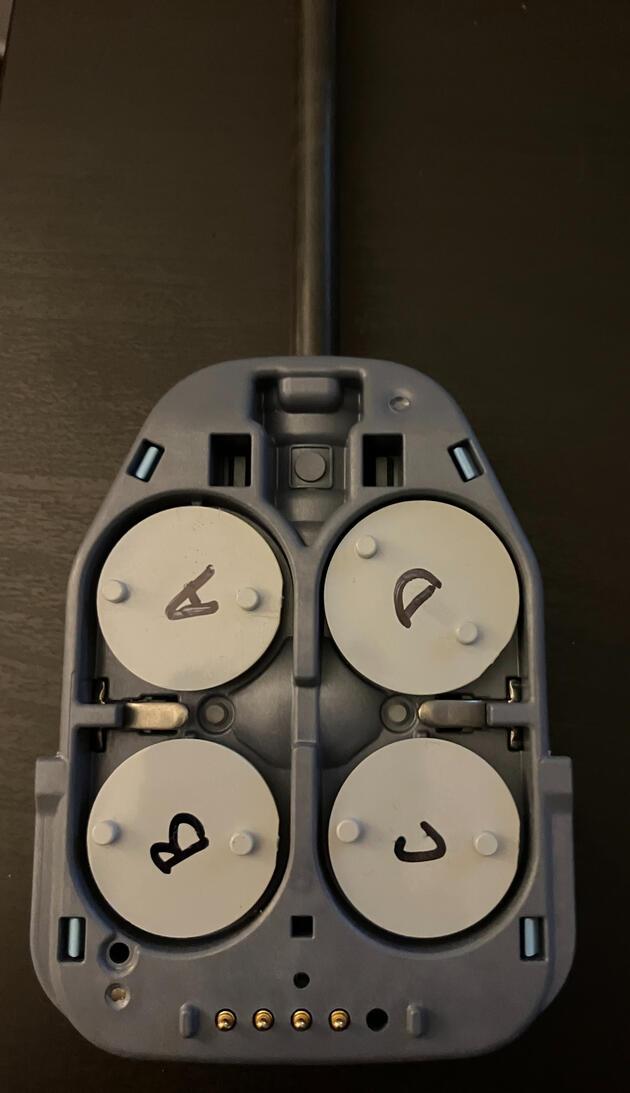

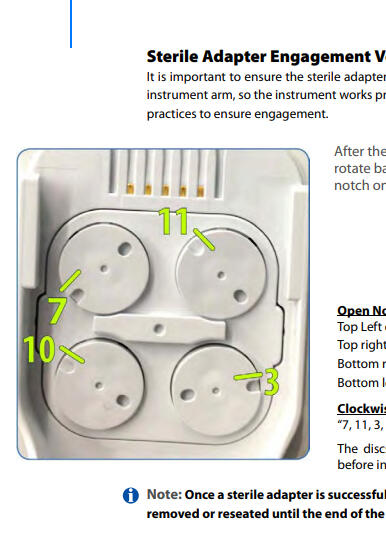

Instrument Layout

To drive the motion of the jaws and EndoWrist a series of pulleys are used. When these disks (A,B,C,D) are rotated an attached cable causes the instrument to move. A, B, and C exhibit coupled motion.

Instrument Motion

A look inside the instrument clearly demonstrates what occurs when these disks are spun. The cables are fed through the instrument shaft where they connect to the pulleys at the wrist and jaws.

Disk-Servo Adapter

Heat set inserts selected to allow parts to be mechanically linked. Metal insert preferable to printing threads since plastic threads will strip over time.

Adapter Prototype

Validated disk adapter design. All disk snapped in place easily and snuggly allowing the device to move when spun. Altered screw depth to mount disks evenly on instrument.

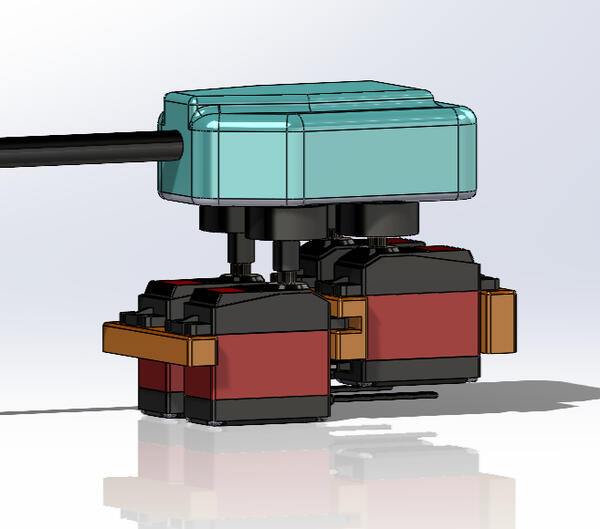

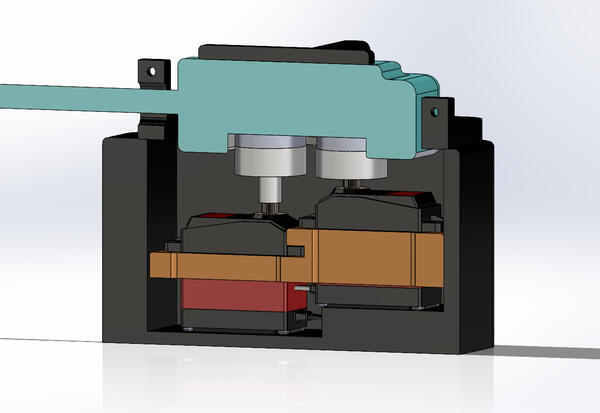

Motor Mount

Modeled all screws and inserts in Solidworks and assembled the module to test fits and clearances. Holes will be modified based on test hole strip results.

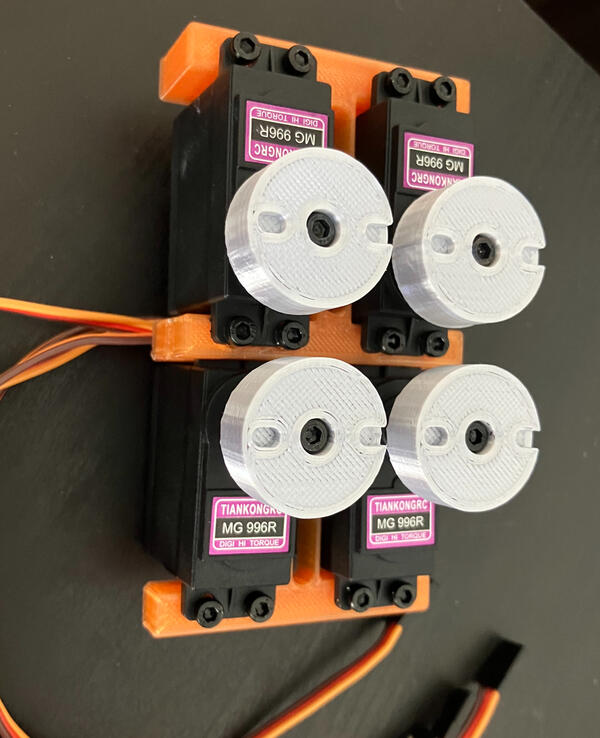

Mounting Prototype

Altered clearances to allow servos to fit easier and reduce material used during printing.

Initial Assembly

Assembled the motor housing prototype and tested fit on the instrument. Parts lined up well.

Housing Clamp

Designing clamping system to keep instrument and disk adapters under constant and even pressure.

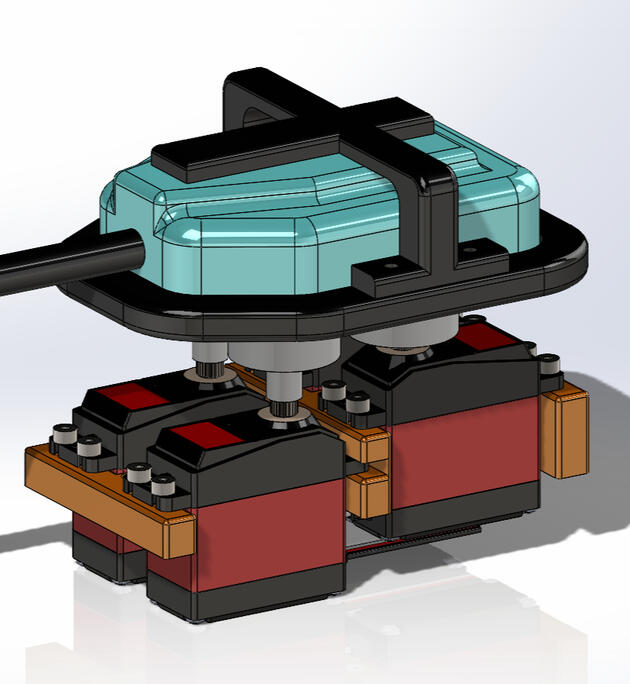

Motor Housing V1

Produced initial motor housing concept design. Servos will reside in the housing and the instrument body will be clamped to the housing.

Housing Internals

See section view for motor resting details. Holes for wires to come.